Next Generation Technology and Infrastructure for Salmon Farming

Existing inshore salmon farming operations in New Zealand are approaching capacity. The NZ Government’s Aquaculture Strategy anticipates $1.5 Bn per annum can be generated through open ocean salmon farming by 2035. The NZ Aquaculture Investment Roadmap is aiming for up to 10 offshore farms producing up to 70,000 to 80,000 tonnes per year.

Ocean Farms has developed technologically advanced offshore farming infrastructure designed for harsh sea conditions known in New Zealand. Our farms can be scaled both in size, shape, and automation level. Over 10,000 hours of front-end design and feasibility work has been completed. A similar prototype mobile unit is now in its third production cycle operating in a Norwegian open ocean location; proving the advancement in sustainability, health and wellbeing for the salmon.

The senior management team behind Ocean Farms in NZ and its partner in Norway have accumulated many years of experience and expertise including the construction of vessels and rigs for the offshore energy industry; delivering solutions to Norwegian and international markets for the past 15 years for a total value of $4 Bn USD.

The Ocean Farms model enables farmers to significantly optimise production, revenue and profit through reducing CAPEX costs upfront. This will significantly lower the financial barrier to scaling the industry. Our farms have minimal environmental impact in the marine environment.

With this emerging alternative to inshore farming, New Zealand can seize the opportunity to transform into a global aquaculture powerhouse, utilising and growing our existing trade routes into SEA and beyond.

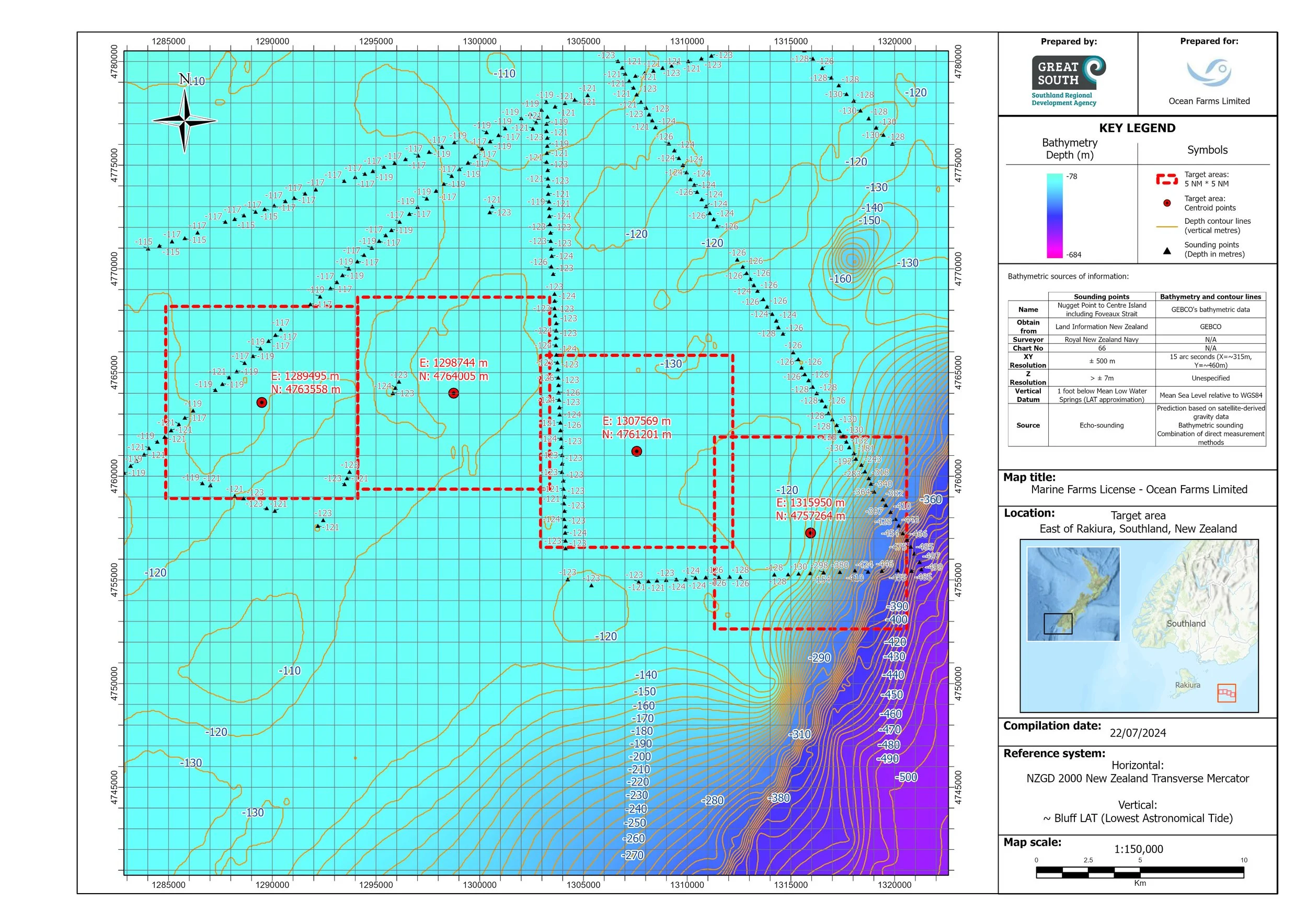

In May 2024, after extensive stakeholder engagement, Ocean Farms NZ commenced the consent process to install and operate HB90 farm facilities at 4 deep-water locations offshore Southland. Each location has capacity for 7500 tonnes. This first wave of farm installations will deliver up to 30,000 tonnes per annum.

To enable the scale up of operations, Ocean Farms has an option on a 15 hectare hatchery and grow out facility directly adjacent to the Southport; 25nm from Ocean Farms offshore farming locations.

Why Offshore Farming?

Rising ocean temperatures continue to have a detrimental effect on fish health in many New Zealand inshore salmon farms.

Our offshore farms are designed to be located in open ocean areas where water temperatures are more consistent with cooler temperatures (10–15°C), have higher oxygen levels and much greater free flow of water, all of which are optimal for salmon health.

Strong ocean currents disperse both any physical parasites and bacteria as well as the micronutrients to which they are attracted, reducing the risk of disease.

Situated in >125m water depth; natural dispersion of residual farming material efficiently occurs eliminating environmental seabed impacts of accumulated bio-waste as is commonly often generated by inshore and coastal fish farms.

Offshore salmon farming allows a very healthy environment for larger volumes of fish to be farmed, providing operational efficiencies for producers.

Technical Characteristics

Hex Box represents high level technology in farming of salmon for offshore harsh environment locations. The company has developed a design which is optimized with respect to cost, weight, operability and flexibility. This is reflected in the shape, hybrid power solution and selection of technical solutions. Hex Box is scalable in size and is based on proven designs which fish farmers are familiar with. The net solution uses existing standard nets but has been modified to incorporate more flexibility with regard to height adjustment. New technology is introduced that monitors fish welfare in order to optimize production and reduce the possibility of lice. Safety of personnel is fundamental to harsh environment locations and this is integrated in the concept from design to operation.

The key features of Hex Box are:

Designed for harsh environment offshore locations

Cost efficiency

Fish welfare improved by hi-tech monitoring and big data sampling and analysis

Designed for existing and future lice prevention and treatment methods

Power efficiency based on hybrid solution and green power production

Safety of personnel is a high priority

Design Parameter & Conditions

Main Conditions:

Design lifetime of 25 years.

Fish-related arrangements and operations based on relevant regulations and recommended practices in New Zealand.

Maritime/Vessel arrangement based on international maritime regulations ratified by New Zealand.

The Unit will have a Class notation by DNV GL (✠ OI Offshore fish farming installation), have no IMO number nor a flag.

Rules, Regulations & Standards:

Maritime/Marine Structure

IMO conventions (International Maritime Organization)

MNZ (Maritime New Zealand)

DNV GL standards, in particular DNVGL-RU-OU-0503

Ballast System

Ballast system compliant to national maritime rules and DNV GL standard with the highest safety level

Designed for 2 compartment damages/flooding in accordance to rules, and will bring Hex Box to even keel within time limit set

Ballasting system bring Hex Box from Biomass draft to Inspection draft

Combined ballast and fire pumps with full redundancy

3 identical pump rooms equipped with high capacity ballast water pumps, stripping ejectors and bilge system

Entire system incl. all valves operated in Kongsberg vessel system at control room and at local operations (maritime regulations)

Hex Box in operation draft (EL. 25m).

Pump room arrangement – Column elevator (red) for easy access.

Pump room arrangement.

Monitoring of Fish

Massive data collection to be used in operation, research and development. Fish behaviour and environmental data will be collected on a server onboard and transmitted to shore.

Sensor package for fish well being monitoring

Image – Kongsberg Maritime

Example of view from one section of cage.

Image – Kongsberg Maritime.

Location

Mooring

Mooring system based on maritime regulations (DNV GL). Identical type of mooring as used on drilling rigs and offshore wind farms.

Designed for 100-year conditions, one-line failure and remain in position

Above - Section view of single mooring line.

No Lines: 6

Total Length: 800m

Chain/Polyester Length: Chain: 50+250m, Polyester: 500m

Diameter: C:100mm R4 P:167mm

Mooring Line Weight: C:356mT P 58mT

Anchor Type: Suction Anchor

A typical setup for single mooring line composition for Hs 12m location:

Highlights

Environmentally friendly and sustainable: Offshore Ocean currents disperse fish waste and leftover food more effectively than inshore salmon farms resulting in improved fish health.

Salmon farming provides a higher edible yield than beef, pork and poultry making it one of the most cost-effective methods to meet the demand of population growth. Salmon is well-placed to capitalize on the growing ready-to-eat (RTE) food market segment, due durability as canned or frozen food.

The average carbon footprint for farmed salmon is 2.9 carbon equivalents per kg of edible product, compared to 3.7, 5.9 and 3.0 carbon equivalents for chicken, pork and beef respectively.

Increasing demand: Driven by an increasing global population, awareness of salmon’s health benefits and a growing middle class.